A full cone nozzle is a type of spray nozzle designed to deliver a consistent, full-coverage spray pattern in a conical shape. It distributes liquid evenly across the entire spray area, creating a dense, circular spray with droplets of relatively uniform size. This nozzle is typically used in applications requiring thorough coverage, such as cooling, dust control, cleaning, and coating processes

TYPES OF FULL CONE NOZZLES

STANDARD FULL CONE (Turbulence nozzle)

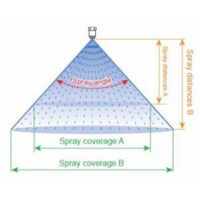

These nozzles employ a specially designed vane at the inlet to impart rotational speed to the fluid passing through. Due to this rotational speed, the fluid exiting the nozzle orifice experiences centrifugal force, spreading out in the shape of a full cone. The angle of the cone is determined by the exit speed (influenced by the inlet pressure) and the nozzle’s internal design, typically ranging from 15° to 120°. Additionally, these nozzles can be manufactured as square full cone nozzles, where the pyramidal spray’s square shape is achieved through a specially designed outlet orifice.

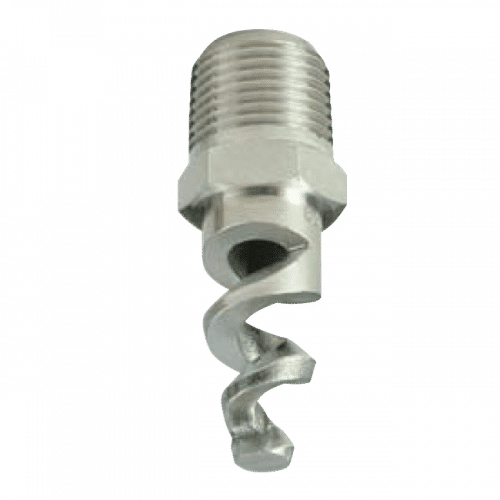

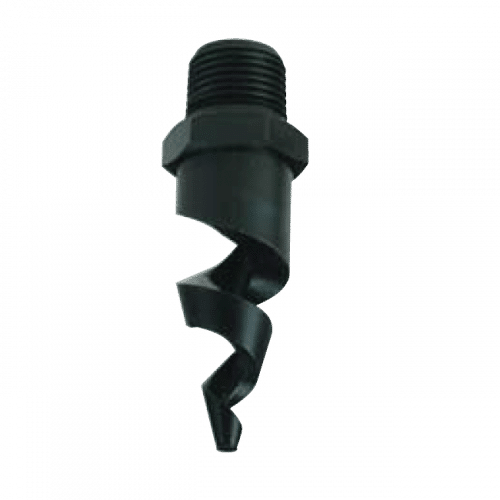

SPIRAL FULL CONE (Impact nozzle)

This nozzle doesn’t produce a true full cone spray but rather a continuous liquid curtain that spirals within a conical volume. While the distribution may be somewhat uneven, this is offset by its exceptional resistance to clogging, large orifice, and vaneless design. These features make it an ideal choice for applications such as wet scrubbers and fire-fighting systems.

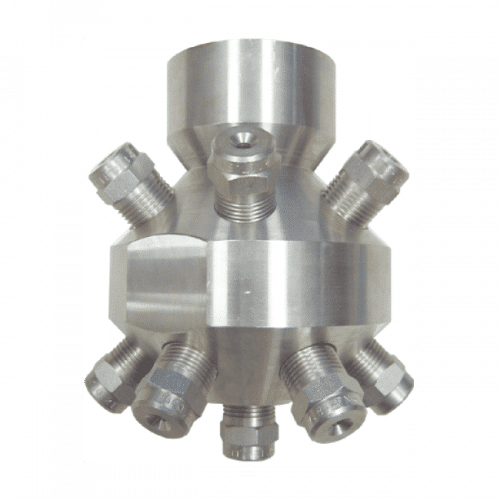

MULTIPLE FULL CONE (Turbulence nozzle)

Several nozzles can be grouped in a cluster with varying spray directions to produce a high-capacity water mist. For applications requiring both large volume and fine mist, multi-orifice full cone nozzles are the optimal choice.

TYPES OF FULL CONE NOZZLE VANES

Slotted vane: named for its spray section featuring six flow slots around its edge and one in the center, generates high-speed rotation of pressurized liquids. These liquids then flow into turbulence chambers, where they are atomized. Slotted vanes offer excellent atomization in a short time, making them effective for cost-saving and suitable for applications with limited space.

Disc vane: With an innovative design and precise machining, this nozzle’s smooth surface minimizes pressure loss and prevents turbulence. It utilizes six peripheral passages to create a swirling motion within the spray chamber. Superficial millings on the underside of the disc act as a brake on the liquid’s rotation at the center, producing a full cone jet with even distribution and finely atomized droplets. The absence of a central hole helps to avoid clogging.

X vane: X vanes are the most commonly used full cone due to their simple design. They feature two sloping flat surfaces that induce a rotational motion in the liquid passing through the nozzle, and two small slots on each flat surface to produce a full-cone spray pattern. The vanes are securely fixed inside the nozzle body to prevent movement caused by size changes due to high temperatures or sudden vacuum conditions in the feed pipe.

S vane: S-type vanes offer a large free passage for liquids through the nozzle, nearly matching the diameter of the spray tip. This design provides the widest possible passage and the highest resistance to clogging among all full-cone spray nozzles with internal vanes.

Spiral vane: The spiral vane is a specialized design used in spiral full cone nozzles. When liquids strike the spiral vane, they atomize and spread to achieve the desired spray angle. This unique design significantly increases both the inlet and outlet diameters of the liquid flow, allowing any foreign particles to pass through without causing clogs. This nozzle design prevents clogging, enhances capacity, and maintains compatibility with standard thread sizes.

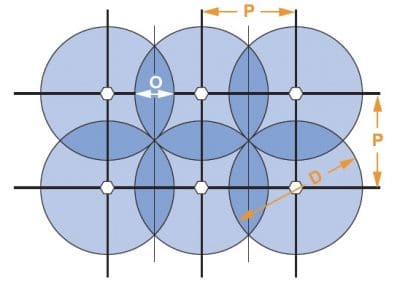

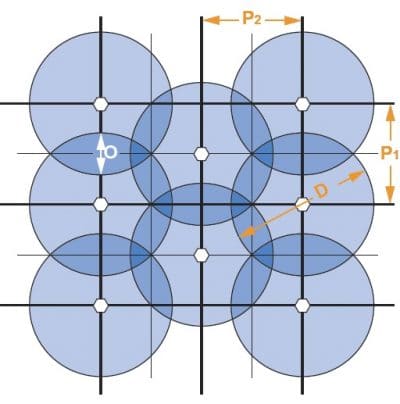

ACCURATE OVERLAPPING OF FULL CONE SPRAYS

When using full and hollow cone nozzles together, achieving uniform spray coverage is crucial. Typically, there are two methods to ensure accurate nozzle settings: matrix configuration and offset configuration. See details below.

Matrix Configuration

Offset Configuration