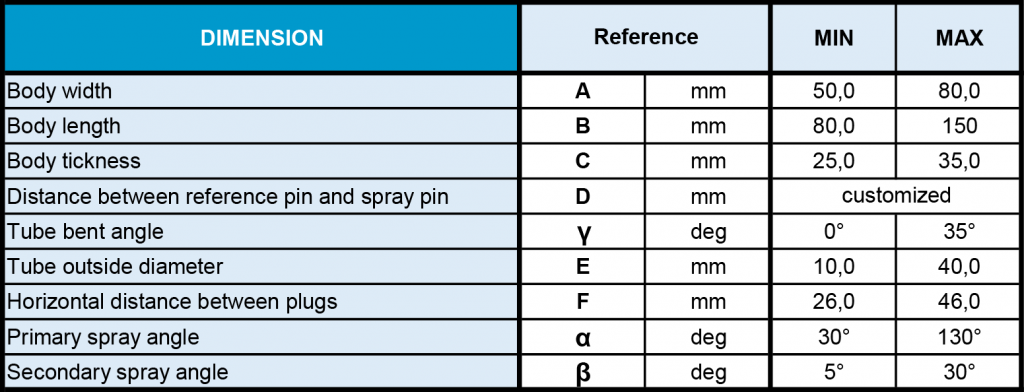

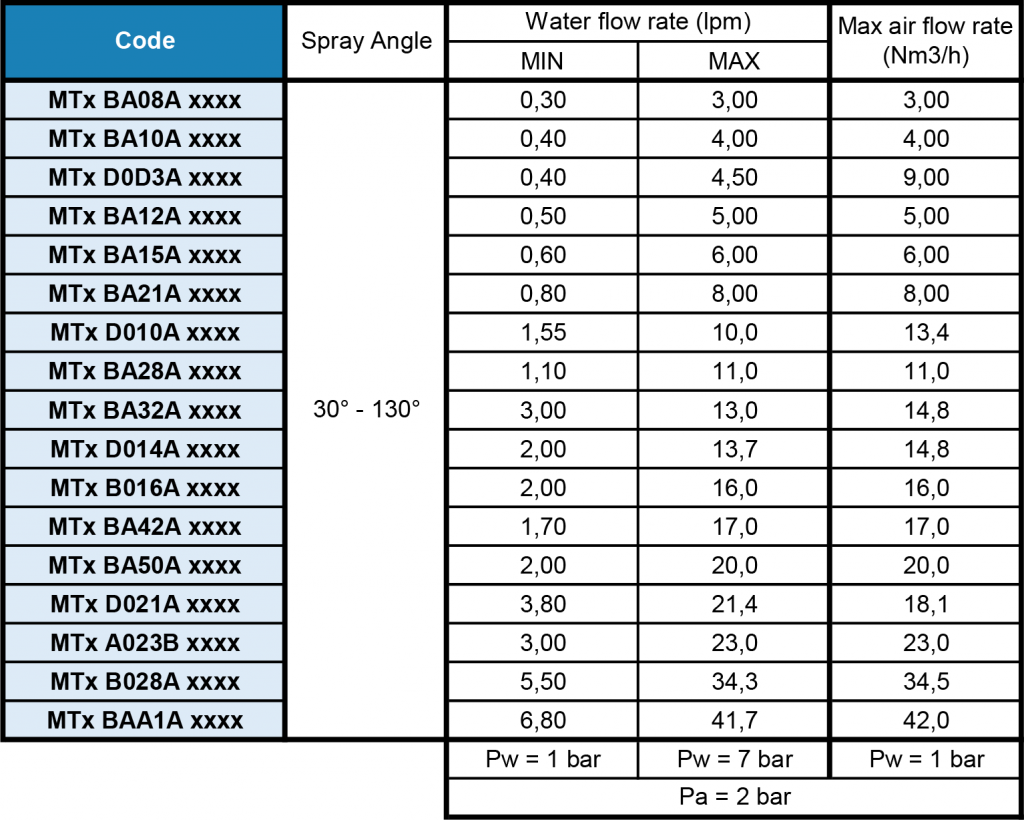

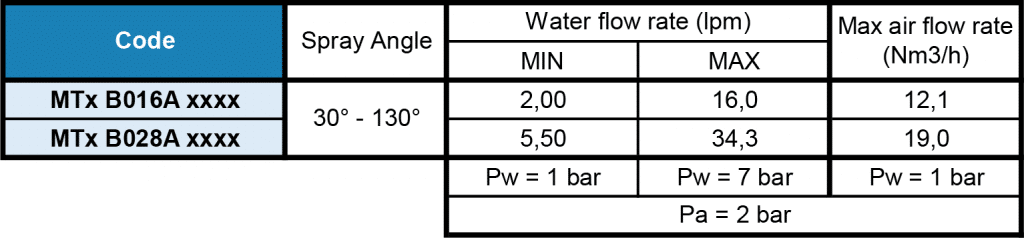

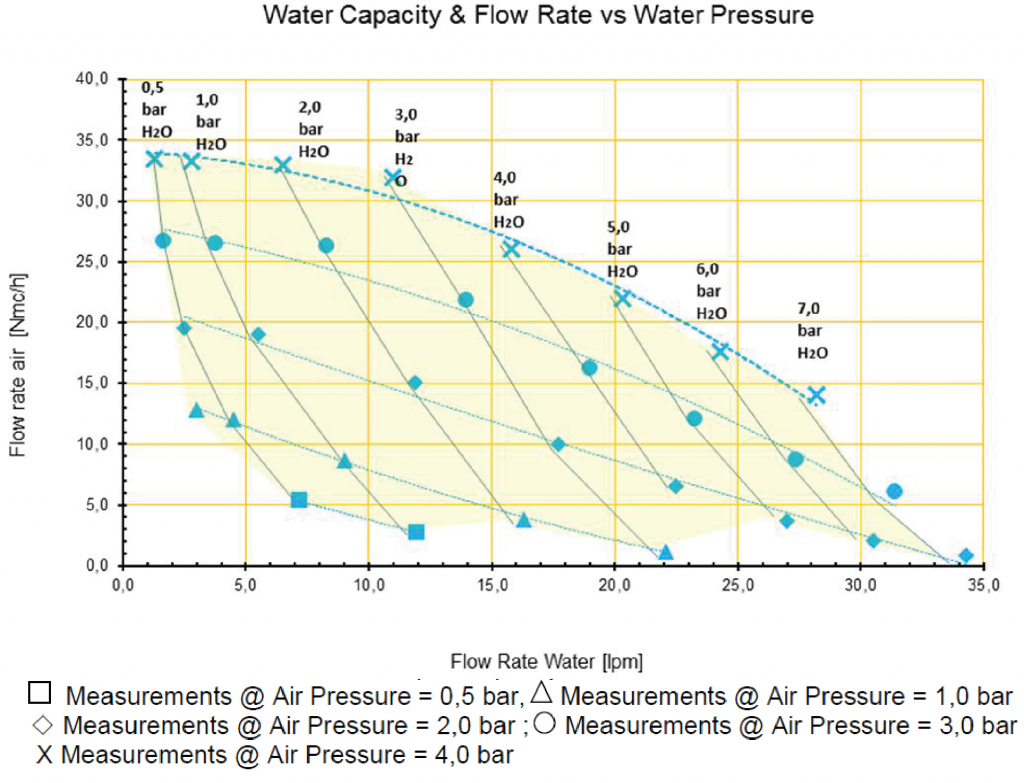

Flow Rate

lpm 0.30 to 41.2

Material

Body: Brass, AISI 3 Tube: Brass, AISI 3 Tip: Brass, Ni-plated brass, AISI 3

Connection

none

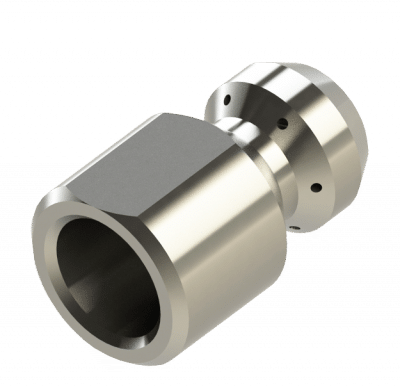

Description

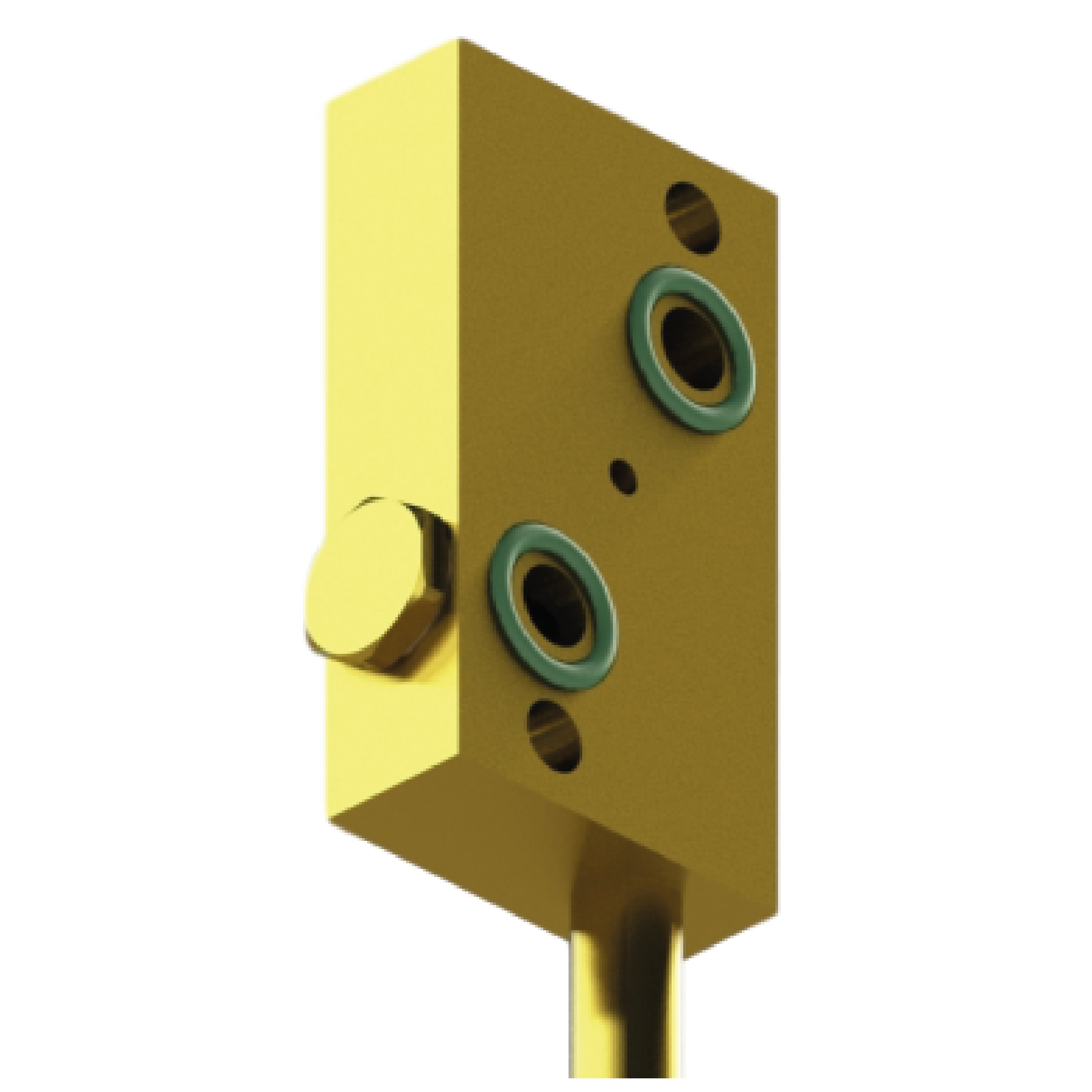

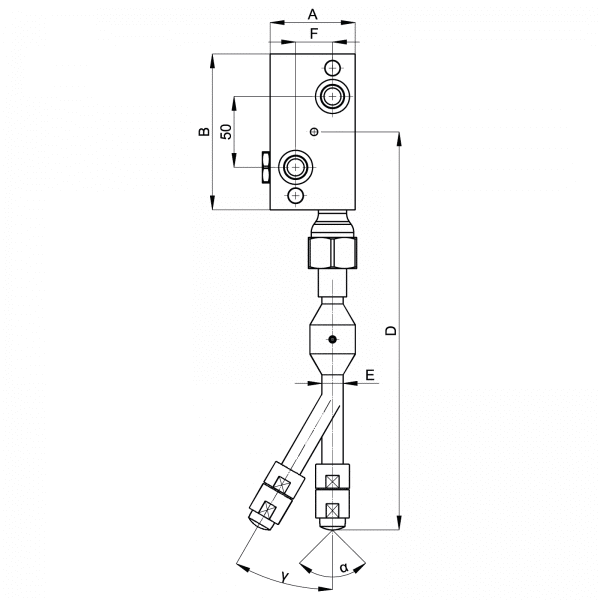

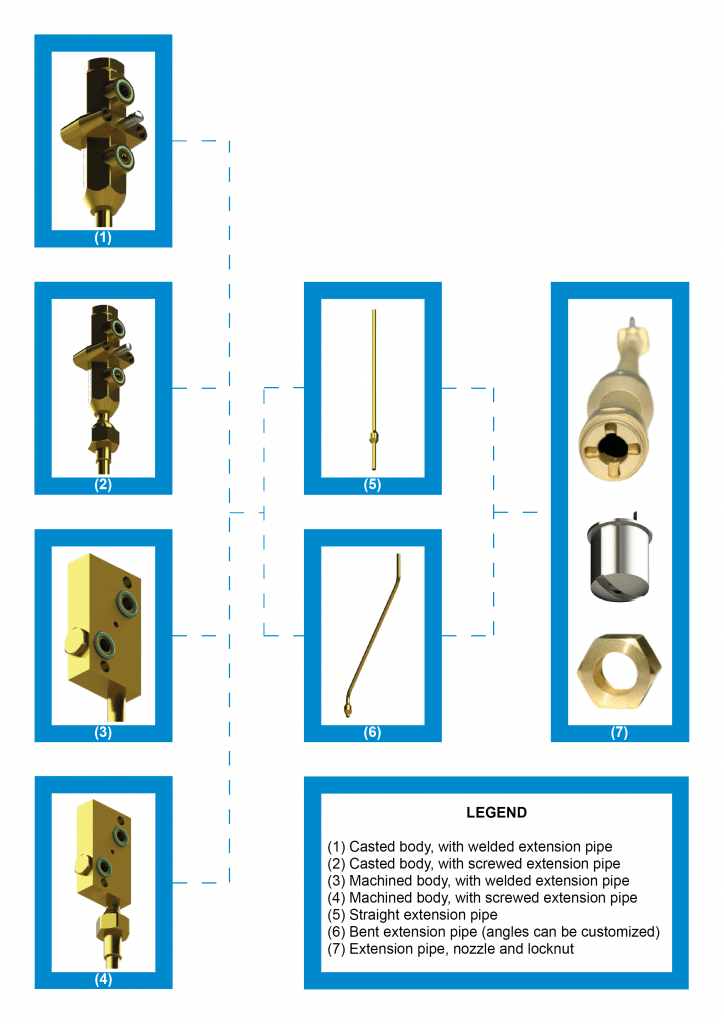

MT – Lance Atomising Nozzle

In continuous casting, and in slab casting in particular, lance atomisers replace conventional compact atomisers, currently called block atomisers, where the atomiser body is equipped with an extension and the spray tip is located at the exit end of the extension. The reasons of this replacement are due either to the geometrical need to insert the spraying pipe between rolls, whose clearance is often very small and prevents the use of block atomisers, or to the convenience to position the feeding pipes far from the intensely heated area near the slabs.

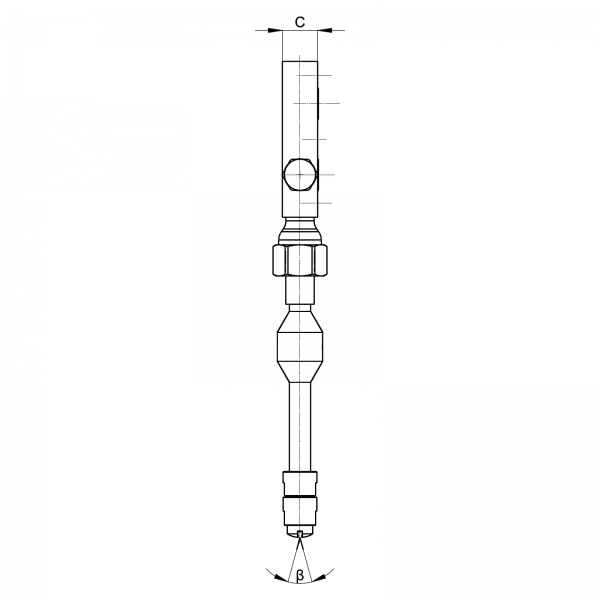

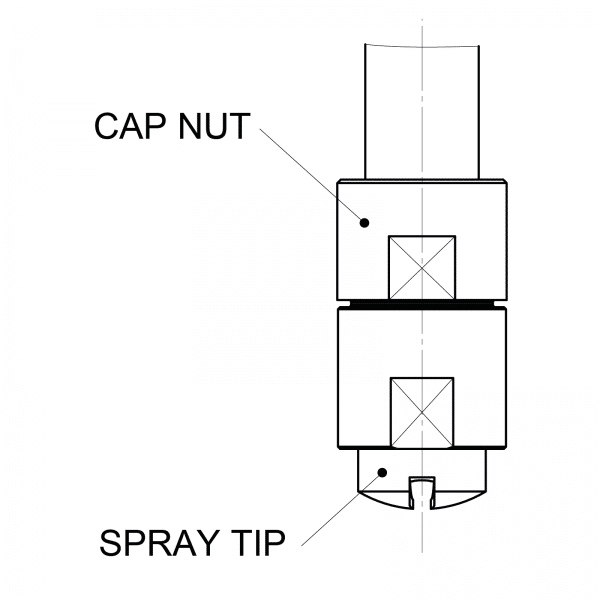

Lance atomisers can be classified according to different parameters: Atomiser’s body: the body where atomization is generated is matched by a plug-in connection to fluid feeding ducts, may have different shapes according to the model and may be casted or machined. Geometry of the pipe: straight pipe, or bent type. Connections of the pipe to the body: the extension pipe is welded onto the block body, or the extension pipe is screwed to the block body with a locknut.