Dust Suppression Award Presented to Tecpro and UOW at Australian Bulk Handling Awards

Tecpro Australia and the University of Wollongong have won a prestigious dust suppression award for their collaborative dust suppression solution at Centennial Coal’s Mandalong Mine.

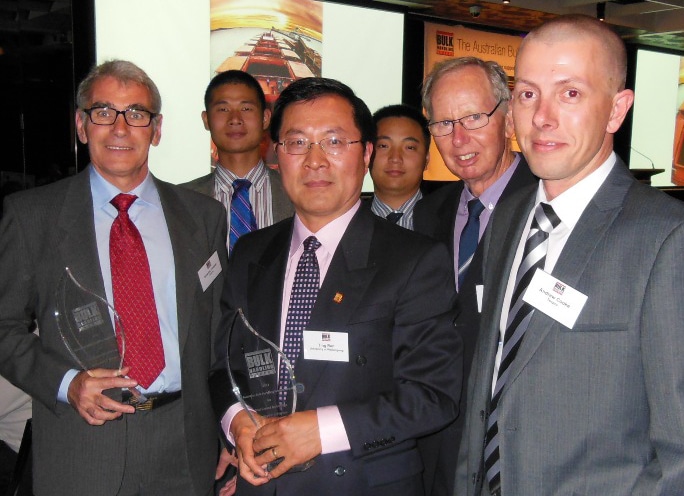

At the seventh Australian Bulk Handling Awards held in Sydney on 7 November, Tecpro Australia and the University of Wollongong won the Australian Bulk Handling Review Award for Dust Control, Technology, Application or Practice.

The award was in recognition of their innovative solution developed to solve a persistent dust problem at Centennial Coal’s Mandalong Mine near Newcastle.

For some time, the mine had experienced a significant dust problem where the coal drops from the crusher to the underground bin.

“After trying a variety of approaches without success, Centennial Coal invited Dr Ting Ren of the University of Wollongong to review the problem,” said Graeme Cooper, Managing Director of Tecpro Australia. “Because we had collaborated with Dr Ren on dust suppression projects in the past, he suggested the mine also contact us to provide expertise on the design of a specialist nozzle system to combat the dust.”

CFD modelling conducted by Dr Ren and his team identified the source and direction of the airflow that was carrying the dust.

“Using the data provided by Dr Ren’s CFD modelling, we produced detailed drawings indicating the optimum position and direction of spray nozzles around the rim of the crusher bin,” said Mr Cooper. “We also recommended the precise types of nozzles to use that would effectively suppress the dust. Many people would be surprised to know there are over 25,000 different types of nozzles that we could choose from, and so it was critically important to know which would provide the best outcome in this setting.”

The solution developed by Tecpro in partnership with the University of Wollongong works by directing a fine curtain of mist inwards from the rim towards the crusher in the centre. Water droplets created by the nozzles are similar in size to the dimensions of the dust particles, making them more likely to attract and combine. Assisted by gravity, the fugitive dust is captured and falls back into the bin instead of remaining airborne.

“The best part about this project is that together with the UOW team, we were able to solve a longstanding problem for our client,” said Mr Cooper. “It’s very satisfying to be able to apply our collective knowledge and experience and come up with an answer to dust problems in challenging environments.”

Air quality in the affected area at Mandalong is estimated to have improved by approximately 90% since the installation of the new dust suppression solution. This has contributed to Centennial Coal’s ongoing program of improving environmental safety.

“It was the first time we’d ever entered a dust suppression award so we were especially thrilled to win,” said Mr Cooper. “It’s wonderful to gain this recognition for the specialised work we do in solving difficult dust problems. We were also particularly pleased to win in partnership with Dr Ren and his team as our expertise complements each other very well.”

For further inquiries regarding Tecpro Australia’s expertise in customised dust suppression solutions, visit our specialist Dust Suppression website:

www.dustsuppressionsystems.com.au or Contact Us today.